Soif

Samsung Interoir Film is well-renowned Interior Film Manufacturer from South Korea. SOIF has developed and supplied by expressing patterns and color texture of various patterns. SOIF’s design is superior compared to the existing finishing materials, the interior finishing materials can be selected according to the atmosphere and purpose of the consumer from natural wood grain type, luxurious metal type, elegant leather and suede type. In addition, Special adhesive treatment allows easy installation on flat as well as curved surfaces, making it more economical and easier to install than other finishes.

.jpg)

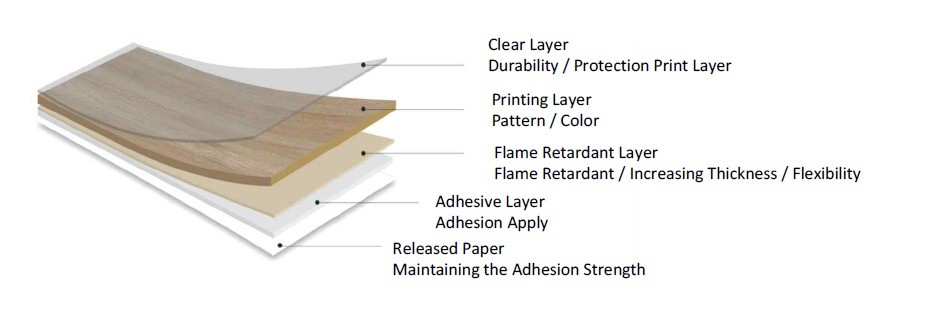

Product Structure

Characteristic

Efficiency

Compared with existing surface finishes, installation is easier, which reduces work schedules. The precision of the work is improved.It is also efficient as it can be easily changed if it needs to be changed or repaired.

Compared with existing surface finishes, installation is easier, which reduces work schedules. The precision of the work is improved.It is also efficient as it can be easily changed if it needs to be changed or repaired.

Design originality

Natural wood grain type and More.

It is possible to produce various colors, Patterns and surface textures such as highquality metal type, leather and suede texture type.

Natural wood grain type and More.

It is possible to produce various colors, Patterns and surface textures such as highquality metal type, leather and suede texture type.

Convenience

Excellent adhesion due to special adhesive treatment for applying on flat and curved surfaces.

Excellent adhesion due to special adhesive treatment for applying on flat and curved surfaces.

Durability

Excellent durability against impact, friction, and scratches. Excellent dimension stability against changes in heat, temperature and humidity, and contamination resistance from solvents and chemicals.

Excellent durability against impact, friction, and scratches. Excellent dimension stability against changes in heat, temperature and humidity, and contamination resistance from solvents and chemicals.

Excellent flame retardancy & Safety

It is a product that passed strict fire-prevention inspection of the KOREA FIRE INSTITUTE.

It is a product that passed strict fire-prevention inspection of the KOREA FIRE INSTITUTE.

Chemical properties

| Test Content | Test Result | Test Method | Memo | ||

| Chemical resistance | Chemical | Result |

Film on aluminium plate Attached After 48 hours soaking in chemicals. Test the damage measurements |

||

| Haptane | No Affect | ||||

| Ethyl alcohol | No Affect | ||||

| Water | No Affect | ||||

| Salibe Water (5%) | No Affect | ||||

| MEK | Damaged | ||||

| xylene | Damaged | ||||

| Flame Retardant | KS Standard | Self-extinguishing |

Film on aluminum plate Flame retardant test after attachment |

||

| Adhension Strength | Surface | Without Primer | With Primer | ||

| (No Primer) | (When Apply) |

2.5 cm wide specimen On each bonded surface attach After 2 days at room temperature Test by Tensile speed 300mm / min. On condition 180 degree PEELTest |

|||

| (kg/25.4mm) | |||||

| Plywood (lauan) | 1.8 | 2.7 | |||

| Plywood (Pine) | 0.5 | 3.5 | |||

| Gypsum board | - | 0.5 | |||

| Asbestos Slate | 0.5 | 3.2 | |||

| Melamine Adhensive Steel Sheet | 3.2 | 5.2 | |||

| Aluminum | 2.5 | 3.5 | |||

| Stainless | 2.7 | 3.5 | |||

| Acryl | 2.9 | 3.5 | |||

| ADF | 1 | 1.9 | |||

Physical properties

| Test Content | Result | Test Method | Memo |

| Dimentional Stability (Shrinkage) | Within 0.1mm |

150mm X 150mm on aluminum plate apply 100mm X 100mm specimen After leaving for 2 days at 65 degrees Measure teh Gap |

|

| Attachment temperature | 18~25 c | Proper Temperature for Construction work | |

| Weather resistance | Not Affect |

XENON ARC LAMP weather resistance tester Discoloration or fading after 300 hours (Irradiation Measuring results) |

|

| Wear resistance | No Change |

TABER wear tester, wear rate CS-17 After testing under 1KG load condition, Surface pattern change measurement (more than 5000 times) |

|

| Heat resistance | No Change |

Attach the film to the aluminum plate After 30 days left at 60 degrees Adhension Measurement |

|

| Moisture resistance | No Change |

Attach the film to the aluminum plate After 30 days left at 40 degrees 90% RH > Adhension Measurement |

|

| Cold resistance | No Change |

Attach the film to the aluminum plate After 15 days left at 30 degrees > Adhension Measurement |

|

| Chemical resistance | No Change |

Drop the materials on the surface After 24 hours, Remove with a blister Measurement of spot occurrence saline Water (1%), Ethanol (50%), Olefin oil, Orange juice, Caustic soda (10%), Coffee, Cola, Milk, Vinegar |